Last updated: 1 May 2023

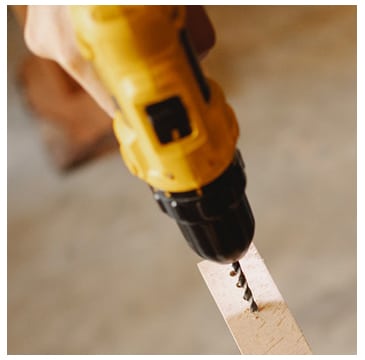

Pre-drilling is always a good idea!

Pre-drilling is always a good idea before driving a fastener because it removes some wood and gives the screw some room to enter the material. This prevents splitting and makes driving the fastener easier. I typically use an electric hand drill in my work, not a drill press, but many of these tips can also apply to a drill press and can even be helpful if you have to drive a screw by hand, so keep that in mind.

Start with a punch

Drill bits tend to wander when they’re getting started. This is because of their spinning motion in the shape of the drill tip. So in any situation where I need a very precise hole placement, I start by punching the hole location. You can do this with an awl a nail set or even just a sharp trim nail. I’ll typically mark the exact location with a pencil then place the tip of my punch right there and give it a little tap. This creates a perfect place for the drill bit to bite in and get started without wondering.

Don’t use too much force

Drill bits like saws should be able to do their job without too much force. The is designed to cut its way through the material. You just need to apply constant pressure. Skinny bits in particular should never be forced because they break easily. If a drill is fighting you it’s probably a sign that the bid is dull think about changing it out or think about trying the next couple tricks.

Clear the swarf

Drill bits are designed to remove wood while boring a hole. The tip initiates the cut then the flutes of a twist bit give the wood a channel to exit through. This waste wood is called a swarf. It’s one of those cool old-fashioned trade labor words. The problem is the drill bit can’t always clear swarf when the bit is embedded. The bit becomes a smooth cylinder and it can’t cut effectively.

You need to back the drill bit out periodically to remove the waste wood. Sometimes if the wood is wet or sappy you may even need to push the swarf out with a knife or your fingernail. But when the swarf is clear the bit will drill much more effectively. So be sure to back the drill out often and make sure that the flutes are clear.

Step up sizes

Another reason drilling may be difficult is that you’re trying to drill too big of a hole too quickly. Larger drill bits have more surface area and more material to clear. The drill is going to have to work harder to do this and it often makes a mess of the wood in the process. You can kill two birds with one stone by starting with narrower drill bits and working your way up in diameter. This makes drilling each pass easier and also prevents your wood grain from tearing out due to excessive friction.

When drilling holes with a diameter of a quarter inch or more, I usually use two or three different drill bits. Hardwoods, in particular, require more bit sizes due to their density. To avoid tear-out when drilling, I have two additional tips which I will explain next.

Use painter’s tape to prevent splintering

Just the cutting action of a drill bit spinning can tear up wood grain and cause unsightly scarring. This tends to be even worse in softwoods like pine. If the appearance of your material matters put a piece of painter’s tape over the place where you’re planning the drill. Then you can mark your location on the tape and drill through it.

The tape adhesive will stabilize the wood grain beneath and prevent the drill bit from doing too much damage as it bores its way through the wood. When the drilling is done you just pull the painter’s tape off but speed also plays an important part in controlling tear out.

Use high speeds for drilling wood

The flutes of a drill bit can rip its wood grain when the bit is moving too slowly. When this happens the bit of sort of plowing its way through the material. You want the bit to spin fast so fast that the flutes don’t have time to grab much wood grain. Instead, the fluids break off wooden micro bits that come away more easily. So high speeds will give you a much cleaner hold when drilling wood but that’s not the metal case.

Use slow speeds for drilling metal

Carpenters don’t work with metal as much as welders or plumbers but it does come up and the key to drilling metal is using slow speeds and pressure. I know I just said don’t use too much force but when drilling metal it does make a difference. Metal wants to carve away and cleaner scoops in wood. Sometimes it comes out in long curlicues or just little chips.

If your bit is spinning too fast it won’t be able to dig in and start scooping it’ll just skip over the surface quickly heating up and dulling itself doing no good. Slow your speed down drastically and use as much pressure as you think the bit will take without breaking. The cutting tip will slowly dig in and begin gouging out material you’ll see a cone-shaped depression forming. Drill until you punch through and then consider letting your bit cool down between rounds of drilling.

Moving on I frequently get asked how big should my drill bit be compared to my fastener. There are charts out there that determine this but who’s gonna stop what they’re doing to look up some engineering chart? Here’s a quicker more convenient trick for deciding what bit diameter you should be using – the “eyeball” method.

The “Eyeball” method

To ensure you’re using the correct drill bit size for your screw, hold the screw up against a light-colored surface and hold the drill bit up next to it. The drill bit should cover the shaft of the screw but not the threads, which are the cutting agents for the screw that carve channels for it to hold in place. This will help you avoid splitting and ensure a secure hold.

So you want the hole to be about as wide as the shaft of the screw but narrower than the threads. Also, remember that hardwoods like walnut will require a slight overcompensation because there’s so much denser you may want to cheat up to a slightly larger bit size to remove just a little more wood. Now if you don’t have a larger bit the next trick might come in handy.

“Hogging out” material

Hogging out is another construction phrase that generally means removing more material by aggressive reaming. For example, a fastener doesn’t want to fit into a pre-drilled hole but you don’t have the next size up the drill bit. You can sometimes get away with running the same drill bit through the hole several times slightly and large it in the process.

You just keep the bit spinning working it forward and backward making sure it contacts the wall to the hole but try not to angle the bit too much because this can deform the hole drastically. And before you remove too much material test the fastener to see if the fit is improved. It’s very easy to overdo things this way but hugging you out is a common technique used on job sites from widening holes on short notice and that includes wood concrete metal and even plastic.

Toenail drilling

The toenail is just driving a fastener at an angle. But drilling at an angle can be tricky because the drill bit wants to run around everywhere. Again that’s just the rotary action of the tool at work. So how can you drill in an angle easily? Start by staining the tool up and drilling vertically at first this lets the drill bit bite into the material and get set when the tip is just slightly embedded you can now tilt the tool down and drive at an angle.

You can carry out this tilt either when the drill is running or when it’s out of stop but make sure you don’t break your bit in the process if it’s already too deep. I usually keep the drill running so it can cut its new channel by adjustment. And finally one last tape trick

Use painter’s tape as a depth marker

This tip is really important when you don’t want to punch through the material you’re drilling. For example, if you want to put a screw in the underside of a nice slab you want to pre-drill enough for the screw depth but no more.

So try this:

- Set the fastener up against the drill bit with the head resting on the tip

- Take a narrow piece of painter’s tape and round wrap it around the drill bit where the fastener stops. I even leave mine a tiny bit shy of that mark.

This way when you’re drilling tape will give you an exact indication of the depth you need. And because I left that little hairline gap I know not to touch the tape to the surface but just to get it close. This preserves the tape for more drilling. You can also hold the drill bit up against the edge of the material you’re going to drill you can set your stopping point based on the thickness of the materials this accomplishes pretty much the same thing.

Final Thoughts

That’s it my best drilling tips and some mistakes to avoid. I hope the post is helpful. If you have any questions please put them down in the comments section or do you know anything I missed let me hear it I love getting tips from my audience.

Leave a Reply